One Team

Accruent solutions for managing assets throughout their lifecycle

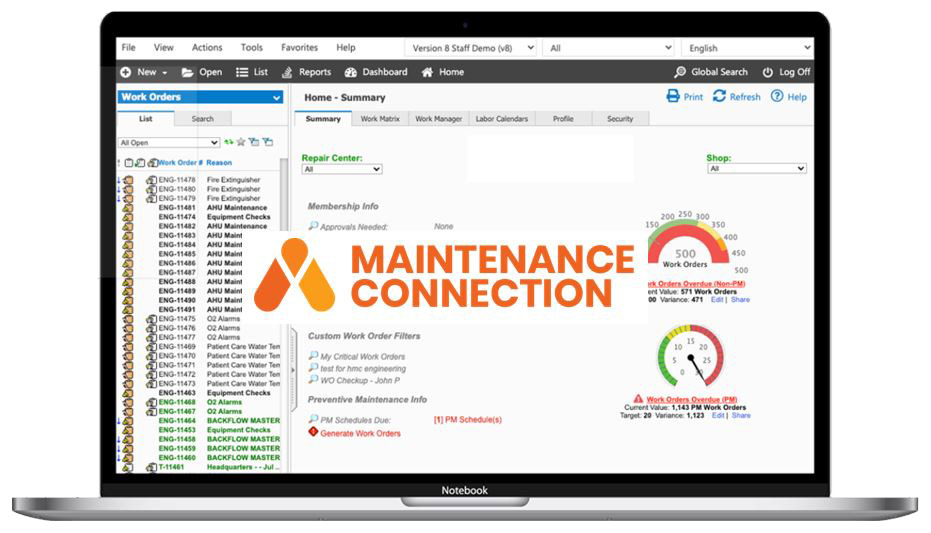

For organizations in asset-intensive industries there are two tools that can improve maintenance and engineering performance: they are a computerized maintenance management system (CMMS) and an electronic document management system (EDMS) . Integrated with each other, they allow you to get the most out of extending the life of the equipment, reducing downtime and improving planning and productivity for all the resources involved.