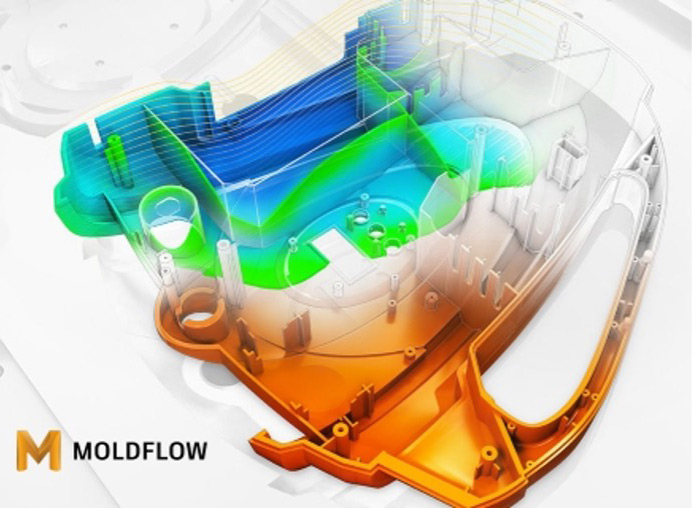

Manufacturing services

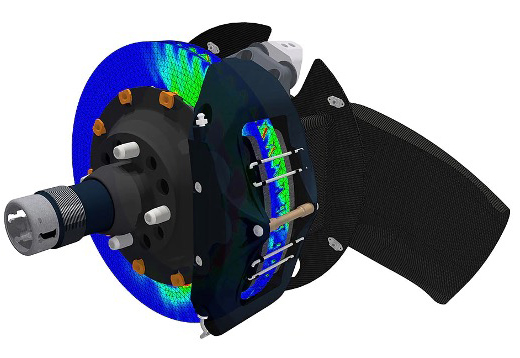

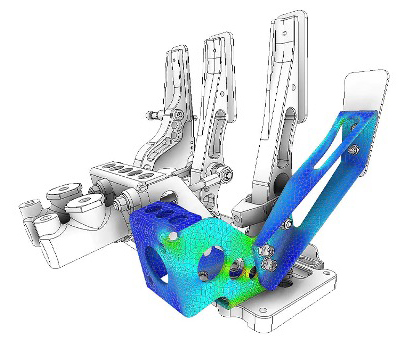

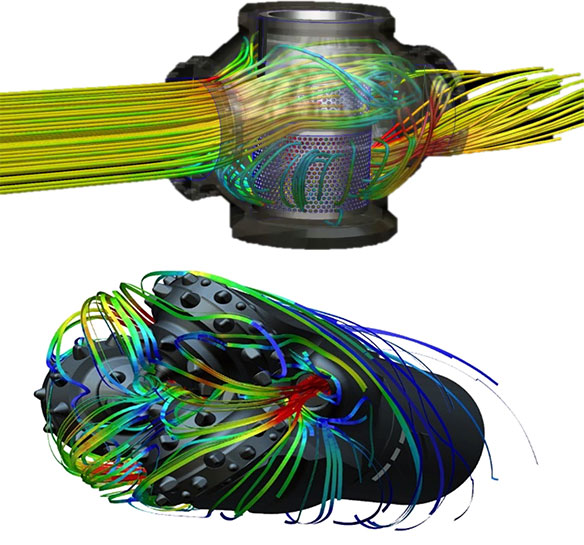

FEM Analysis

What purpose does it have? Essentially, to reduce to a minimum expensive real prototyping and put on the market faster your products.

It is also needed to keep under control many structural aspects, parts worn-out, thermal transfer, vibrations, impacts, non-linearity. These are fundamental aspects to obtain reliable and efficient products, in line with the fast-paced evolution of the market.